Stainless

35+

Years Experience

about us

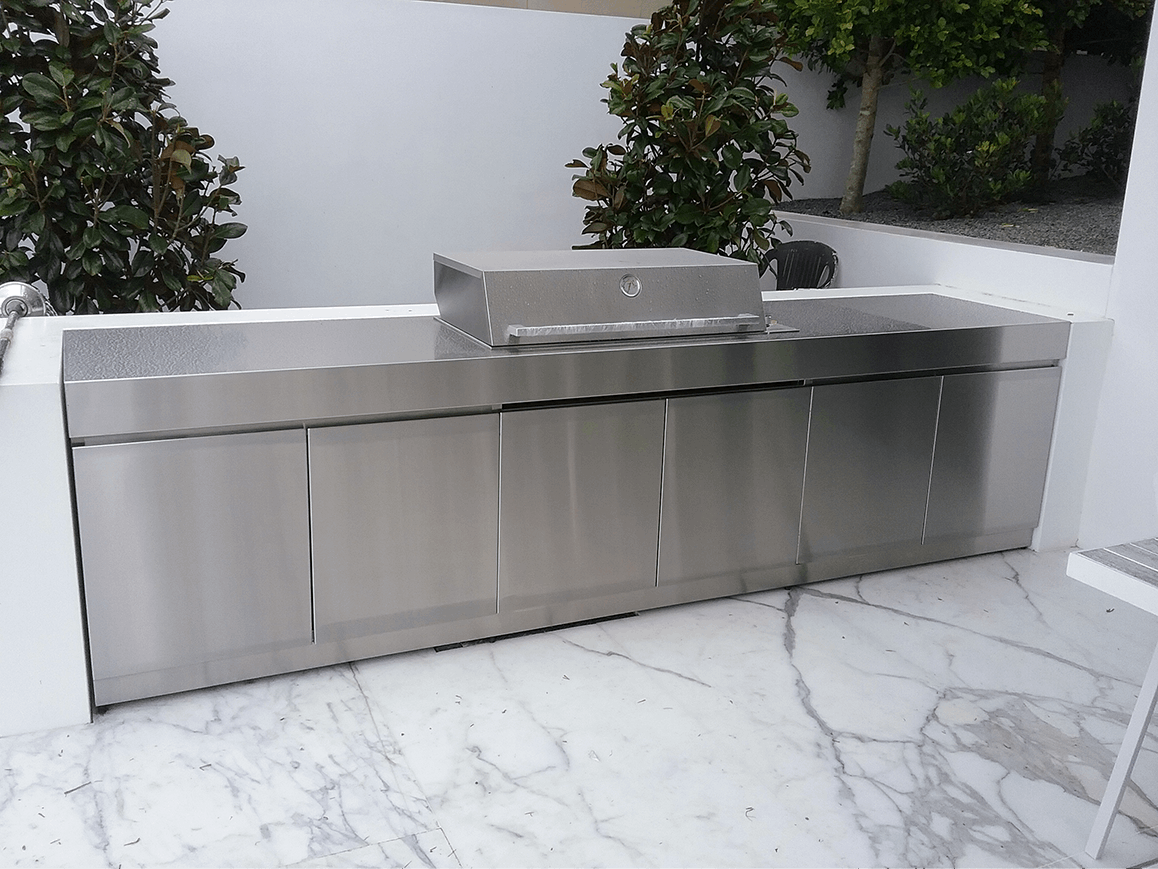

Our Stainless Division has developed an outstanding reputation for high quality custom made stainless fabrication, installation and stainless sales in set lengths or cut to size, for

residential and commercial use. Our Stainless team has in excess of 35 years stainless experience and we pride ourselves on the quality of our design, manufacture and premium materials used in all our fabrication and installations.

Our custom stainless fabrication services deliver the ultimate solutions for projects of any shape and size in:

Food Grade 304 Stainless Steel – for benches and bench tops, cabinets, trolleys, splash backs, wall panels, integrated sinks, cook top surrounds, shelving and counters, used in projects for restaurants, cafes, bakeries, mobile food vans, school canteens and domestic kitchens.

Marine Grade 316 Stainless Steel – for outdoor entertainment units, BBQ cabinets, hand railings, balustrades, furniture, letter boxes, tanks, marine components, brackets and water features used in multiple commercial and domestic applications.

Our custom stainless innovations are limited only by your imagination!

From your requirements - to our check measure or quote - from our fabrication - to supply

and/or installation – with our expertise you can be assured of our care and prompt efficient

service by a small team who handle your project personally and have a passion for getting

the end result right.

What We Do

Our Process

02

Plan & Design

With so much experience under one roof the preparation of your plans or workshop drawings is supported throughout your approvals process, including site measures. Alongside our inhouse team Highlander Metals engages fully accredited businesses to provide workshop drawings when required.

04

Install

Site work is a challenge, no two sites are the same and with all the preparation work undertaken, real world dynamics will present different problems. If this happens, you will want an experienced team of can do, problem solvers on site.

01

Scope of Work

Understanding the end product and exactly how to complete the steps necessary is the most crucial aspect of our customer service. The team at Highlander Metals commits to ensuring that the scope is fully understood for all parties concerned. This ensures the best possible foundation for all.

03

Fabricate

The fabrication process begins almost immediately with sourcing the materials for our awesome fabricators to do their best work. All preparation work for final finishes such as galvanising and powder coating is completed above required standards.

What We Do

Our Process

01

Scope of Work

Understanding the end product and exactly how to complete the steps necessary is the most crucial aspect of our customer service. The team at Highlander Metals commits to ensuring that the scope is fully understood for all parties concerned. This ensures the best possible foundation for all.

02

Plan & Design

With so much experience under one roof the preparation of your plans or workshop drawings is supported throughout your approvals process, including site measures. Alongside this inhouse team Highlander Metals engages fully accredited businesses to provide workshop drawings when required.

03

Fabricate

The fabrication process begins almost immediately with sourcing the materials for our awesome fabricators to do their best work. All preparation work for final finishes such as galvanising and powder coating is completed above required standards.

04

Install

Site work is a challenge, no two sites are the same and with all the preparation work undertaken, real world dynamics will present different problems. When this happens, you will want an experienced team of can do, problem solvers on site. Hello!